Final Confirmatory Functional Testing of Chernobyl’s Used Fuel Storage Facility Begins Today with Handover to the Owner Expected this Summer

Holtec, Marlton, NJ

Holtec, Marlton, NJ

Mon, May 6, 2019

|

We are pleased to announce the start of final system-wide trials for Chernobyl’s dry store facility today. These functional dry runs follow a long series of exhaustive tests of the individual systems, structures and components within the spent nuclear fuel processing and storage complex called ISF-2. Over the next two months, we expect to complete stem-to-stern functional demonstrations of the spent fuel handling and storage processes before handing over the facility to Ukraine’s State-owned enterprise Chernobyl Nuclear Power Plant (ChNPP). ChNPP will then initiate commissioning of the facility beginning with “hot” confirmatory tests. To be sure, dismembering more than 21,000 RBMK spent fuel assemblies in a special purpose “Hot cell,” packaging those fuel assemblies in double walled canisters (DWCs), and transferring them from (open) water-cooled pools into hermetically sealed rugged helium-filled storage systems inside ventilated modules will mark a huge safety milestone for Ukraine. This project is funded by a group of Western countries and Japan and is administered by the European Bank for Reconstruction and Development (EBRD).

|

|

|

|

Holtec International took over the ISF2 project in 2011 after a multi-year demonstration to EBRD and the Ukrainian regulator that the Company had the necessary technologies to deal with Chernobyl’s notoriously water-logged RBMK fuel and onerous fuel confinement requirements. The project had begun in the late 1990s but was stalled when the prior contractor’s technology was shown to be inadequate to meet the facility’s functional and regulatory requirements. The partially constructed facility and major civil equipment structures remained idle for nearly a decade, its equipment and machinery ravaged by time and weather. The project sponsors made the decision to award the contract to Holtec International in 2011, with the project came the unenviable task of restoring the facility which suffered from a litany of infirmities, most unexpected. The result has been a patient multi-year assembly and repair operation that has required remedial work on virtually every one of the over 150 systems that comprise the facility. “We were handed a facility full of defective equipment that had deteriorated for lack of any maintenance for nearly a decade,” says Holtec’s Project Manager Michael Pence. “Through the sheer commitment of our team and partners, this project, which looked nearly impossible given the poor condition of the building, shabby documentation and old equipment, with little or no hope of available replacement parts, has now reached the milestone we celebrate today.”

|

|

|

|

|

|

ISF-2 Facility

|

|

|

|

Partial top view of the ISF-2 Hot Cell

|

|

|

Soon the responsibility to operate this vitally important facility will devolve to ChNPP. We expect ChNPP to rise to the challenge and gird themselves for the next critical stage – actual fuel loading – of world’s largest used fuel inventory. We consider expedited transfer of the long-stored RBMK spent fuel assemblies from the aging ISF1 wet storage facility into dry storage to be a national safety imperative for Ukraine.

|

|

|

|

“We thank our principal subcontractor, UTEM and their hundreds of workers, along with numerous other key Ukrainian and European suppliers and subcontractors for their tireless efforts and unwavering commitment. The ISF2 site construction work has been an exemplary model of personnel safety. We would also like to express our sincere thanks to the national regulator, SNRIU, for their constructively critical posture throughout this difficult project,” offers Thomas Marcille, Holtec International Vice President and senior executive in charge of Ukraine. Echoing Marcille, Holtec Ukraine’s Director General Sergiy Tarakanov notes, “Completing ISF2 to this point has only been possible through hard work and cooperation with the project’s numerous stakeholders and suppliers, and by the incredible commitment of Holtec International associates at the site and from our other global operational centers. We stand ready to assist ChNPP in the critically important fuel transfer campaign if necessary.”

|

|

|

|

|

|

Process of SNF transportation from the existing storage facility into ISF-2.

|

|

|

We should note that Holtec International in partnership with our client Energoatom is completing the Central Spent Fuel Storage Facility (CSFSF) for the country which is completely separate from the ISF-2 project. The CSFSF is envisaged to receive and store spent nuclear fuel assemblies from the country’s operating VVER reactors. Like ISF2, CSFSF will employ double-confinement DWCs, the world’s first double-walled, double-lid multi-purpose canister system for dry storage of spent nuclear fuel. Vital to Ukraine’s energy security interests, CSFSF will allow Energoatomto safely transport and store the lifetime spent fuel inventories from its operating VVER fleet, while averting the need to purchase storage services from the Russian Federation. CSFSF will enter full operation in 2020.

|

|

|

|

For more information, please contact:

Erika Grandrimo, Publisher

Phone: (856) 797-0900, ext. 3920 | Email: e.grandrimo@holtec.com

|

|

|

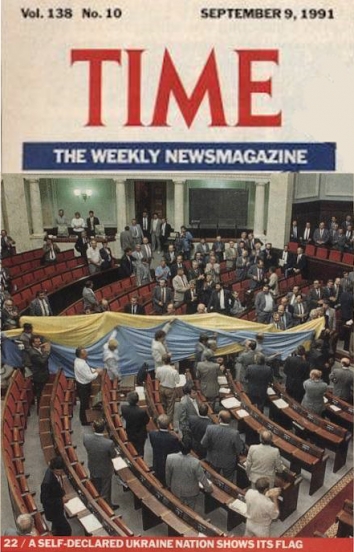

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec, Marlton, NJ

Holtec, Marlton, NJ