|

Jupiter, Florida; In 2016, we completed 30 glorious years of operation. By every measure, our Company has performed spectacularly - growing employment at every one of the Company's operation centers, rising sales, soaring capital investment, increasing annual revenue, EBIDTA & net income, strengthening employee satisfaction scores, excellent nuclear quality and timely delivery metrics, a robust culture of innovation as measured by new patents issued to the Company and, above all, a worker safety record at our manufacturing plants and power plant sites that is among the best-in-class in the nation.

As 2016 recedes into history, let us salute the spirit of those members of our Holtec community who are bravely battling serious illnesses. It is their undaunted resolve to overcome their personal misfortune that represents the true spirit of our Company and our Holtec community.

We should thank our talented and industrious associates at the various Company operation centers whose relentless drive for excellence in their everyday work has made us among the most admired companies in the power industry.

In 2016, we launched the HI-STORE CIS initiative in collaboration with our New Mexico's host communities represented by ELEA, LLC to store America's used fuel presently stranded at nuclear plants across the country; in 2017 we will drive it closer to a licensed reality. Our SMR-160, a lonesome endeavor for the past five years supported entirely by our own funds, will likely attract some visionary investors in 2017. We are convinced our SMR-160 small modular reactor is the most credible carbon-free solution for our power-hungry planet. We expect 2017 to validate our belief in the "walk-away safe" SMR-160 reactor as we drive the program through its final stages of safety evaluation.

In 2016, we also launched Team Holtec, an alliance of North America’s premier nuclear design and construction companies to carry out what we call proto-prompt decommissioning of shuttered nuclear units, whose numbers, sadly, are on the rise. Working with our alliance partners, we have embarked on an engineering-fueled initiative to make decommissioning a safe, low dose, and predictable cost endeavor. By leveraging our expertise in used fuel and nuclear waste management, we are poised to introduce innovative processes in a field that has been woefully devoid of technical innovation.

On the last working day in 2016, all buildings and structures constructed at our technology campus in Camden received temporary certificates of occupancy. In a typical Holtec way, our project team reached this milestone over a year ahead of the specified schedule! Next, the manufacturing plants will be outfitted with the latest in equipment and machinery - some larger than a typical apartment in size! Starting in mid-February, our Marlton staff will begin relocating to the $312 million-dollar sparkling new campus on the Delaware River in South Camden. We are thrilled at the prospect of our designers, analysts, thinkers, innovators, inspectors, and project managers rubbing elbows everyday with our green collar workers in a nurturing technical work environment. I am confident our campus will be ground zero for the renaissance of manufacturing in America. Locating to one of the poorest cities in America gives us the unique advantage to train the city's young and the poor and thus making a difference in their future which is often imperiled by the blight and deprivation that surrounds them.

As we recruit new personnel to staff our Camden campus, we need to remember our commitment to diversity and meritocracy. We must safeguard the ethos of fairness and team work that has propelled our growth over the past three decades.

In the past 30 years, we have made several transformative improvements in those industry sectors where we operate. We transformed wet storage of used fuel in the 1980s and 90s followed by similar technology strides in dry storage over the past 25 years.

After 10 years of applied research, we now have the manufacturing capability to produce tube bundles for Air Cooled Condensers (ACCs) with stainless steel core tube – the world's first. Our ACCs replace water as the cooling medium (an increasingly scarce resource) with air to condense power and process plants' waste steam. Our ACC is an environmentally noble technology which is what Holtec is all about.

I wish our readers a Happy New Year.

- Dr. Kris Singh, President & CEO

|

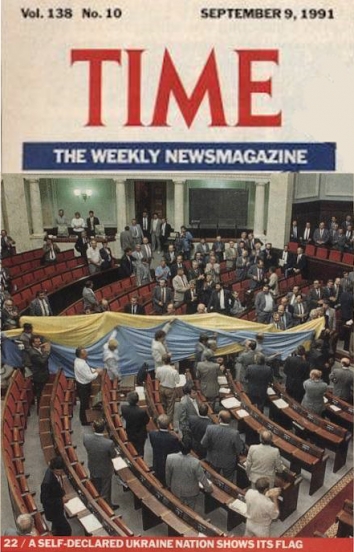

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

"HOLODOMOR 1932-33: THROUGH THE EYES OF UKRAINIAN ARTISTS" - COLLECTION OF POSTERS AND PAINTINGS

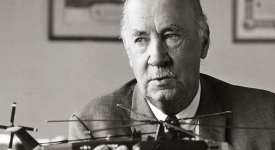

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

USUBC COLLECTION OF HISTORIC PHOTOGRAPHS ABOUT LIFE AND CAREER OF IGOR SIKORSKY PHOTOGRAPHS - INVENTOR OF THE HELICOPTER

Ten USUBC Historic Full Page Ads in the Kyiv Post

Ten USUBC Historic Full Page Ads in the Kyiv Post

Holtec International, Marlton, NJ

Holtec International, Marlton, NJ