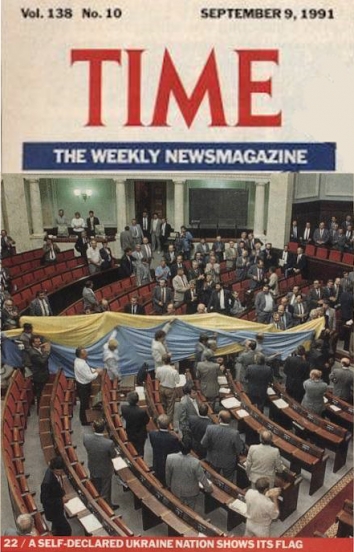

Featured Galleries USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

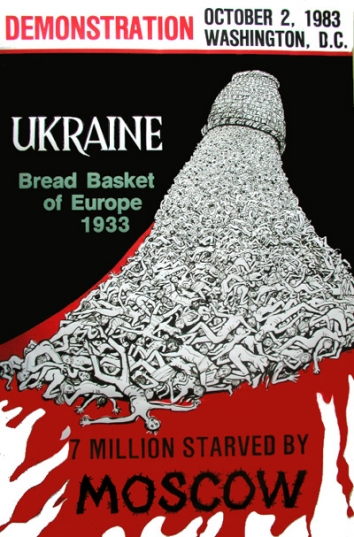

Holodomor Posters

Holodomor Posters

Bidding Adieu to 2011, Welcoming 2012

Holtec International 2011

Saturday, December 31, 2011

On behalf of the associates of our seven operation centers based on three continents, we extend our New Year greetings to Holtec International’s clients and suppliers - our vital stakeholders - who helped make 2011 a splendidly successful year for the Company. In 2011, Holtec completed 25 years of operation with a proud record of continuously rising employment in our factories and offices fueled nearly entirely by the sale of new products and systems developed by the Company's own engineers. In its core business of spent fuel management, Holtec’s relationship base in wet and dry storage/transportation grew to over 120 nuclear plants around the globe.

Holtec’s committed and derivative backlog across all product lines offered by the Company now exceeds $5 billion. In 2011, Holtec became the first company to establish a comprehensive training center for dry storage implementation and in November became the first company to complete a Client Assisted Turnkey dry storage project (at Waterford). The second Client Assisted Turnkey dry storage project, at Comanche Peak, is scheduled begin the final phase of the project, fuel loading of 12 HI-STORM systems, in February of 2012 (dry runs were completed July 2011).

In the area of heat transfer equipment, our historical field of technical dominance, the number of power plants that employ Holtec's water and air cooled steam condensers, feedwater heaters and auxiliary heat exchangers now exceeds 100. In 2011, Holtec introduced the vertical air cooled condenser, called HI-VACC, that has been hailed by many as a transformative technology which will make power plants in the water challenged and land constrained regions of the world feasible.

Holtec's drive to place vital nuclear materials underground (and thus beyond the reach of terror), began in 2009 with the USNRC certification of HI-STORM 100U, continued in 2011 with the development of HI-STORM UMAX and HI-STORM SUBTERRA models, the latter ideally tailored to serve as an interim storage facility. Both systems will be submitted for USNRC licensing in 2012. The entire planned capacity of the Yucca Mountain repository - 70,000 metric tons of spent fuel - can be stored in HI-STORM SUBTERRA in an at-will retrievable configuration on merely 16.5 acres.

The most prominent underground initiative, however, is the successful culmination of the proof-of-principle studies and advancement in the design of HI-SMUR 140 (Holtec Inherently Safe Modular Underground Reactor) which envisages placing all of the plant's nuclear units fuel in a below-ground, impregnable configuration while relying on no active source of power for its operation or shutdown. Passive in every aspect of its operation, the key design features of HI-SMUR 140 present a fail-safe technology in the wake of the cataclysmic events at Fukushima Daiichi. HI-SMUR 140 is a bold attempt by our company to make small reactors an indisputable epitome of safety and security, affordable for the emerging economies as a carbon-free source of reliable energy, palpably terror-resistant and hence, a ubiquitous source of energy around the globe. Prodded by a strong market interest, Holtec plans to accelerate the development of HI-SMUR in 2012.

Another Fukushima-inspired technology developed by the Company is HI-COOL, which will passively remove the decay heat from a fuel pool or a reactor cavity without requiring any source of power.

In 2011, Holtec’s plants in Pittsburgh, PA, Orrville, OH and Lakeland, FL, each reached record levels of on-time delivery of equipment. Even more important, thanks to the incessant management drive to indoctrinate a strong safety culture, safety performance of all of our three shops has zoomed to the top tier in the industry.

Holtec's founder and CEO, Kris Singh, has declared 2012 as the year of excellence in human performance for the Company's workforce with a target of 80 percent reduction in the number of human errors in all phases of our operation, including engineering, manufacturing, quality assurance, and site services. In our drive to meet the goal of excellence, we are proud to enlist the support of the 700 men and women who call Holtec their professional home.