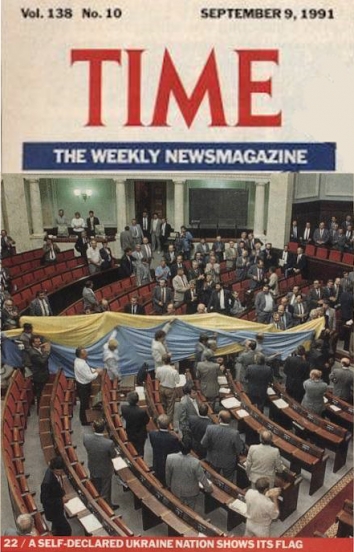

Featured Galleries USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

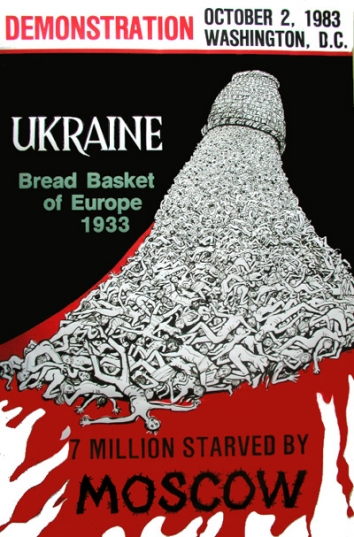

Holodomor Posters

Holodomor Posters

Exelon Generation Company, LLC Selects HI-STORM FW For Use At Clinton Power Station

Holtec International, Kyiv, Ukraine, Monday, March 04, 2013

Holtec International, Kyiv, Ukraine, Monday, March 04, 2013

Holtec International is pleased to announce the Company has signed a contract with Exelon Generation Company, LLC (Exelon) to provide the HI-STORM FW (Holtec International Storage Module Flood and Wind) Dry Cask Storage System containing the MPC-89 for deployment at Clinton Power Station (Clinton), located near Clinton, Illinois. Exelon’s selection of Holtec’s highest capacity dry cask storage system, marks Exelon’s first implementation of the HI-STORM FW, enabling Clinton to store 89 used fuel assemblies in oversized storage cells with as little as three (3) years of cooling time.

Holtec® was awarded the Dry Storage contract through a competitive bidding process. Holtec’s contract includes the initial supply of eight (8) HI-STORM FW and MPC-89 systems, as well as one (1) HI-TRAC VW (VW for Variable Weight) transfer cask, and all necessary ancillaries to support Clinton’s initial dry storage loading campaign in 2015.

Clinton is the sixth Exelon site to implement Holtec’s dry cask storage systems. Exelon currently has over 110 HI-STORM 100 systems (the predecessor to Holtec’s highest capacity HI-STORM FW System) loaded at Braidwood, Byron, Dresden, LaSalle, and Quad Cities combined. Exelon’s selection of the HI-STORM FW for use at Clinton permits a maximum heat load of over 46 kW in the MPC-89.

This high heat load provides Clinton the flexibility to develop an optimized loading strategy through the end of plant operation. The entire multi-purpose canister basket in the MPC-89 is manufactured from the industry’s first nano-particle based neutron absorber material, Metamic-HT. The low weight of the Metamic-HT fuel basket frees up valuable weight for adding shielding to the transfer cask. All equipment will be domestically fabricated at Holtec’s manufacturing facilities; namely at the 660,000-square-foot Holtec Manufacturing Division (HMD), located in Turtle Creek, Pennsylvania and at the 300,000-square-foot Orrvilon facility located in Orrville, Ohio.

Mr. Max Hollinden, Exelon’s Project Manager, stated “The higher capacity was the primary driver for selection of the MPC-89 System. This should lead to reduced duration of campaigns and associated reduced dose to the workers.”

Ms. Joy Russell, Holtec’s VP of Business Development, thanked Exelon for continuing to place their confidence in Holtec and added, “Holtec is pleased to be selected by Exelon to continue to serve their dry storage needs with the addition of Clinton to the fleet of Exelon sites located in the Midwest already using the HI-STORM system. We are committed to the successful execution of the dry storage project at Clinton and look forward to continuing to build upon our long-term partnership with Exelon.”