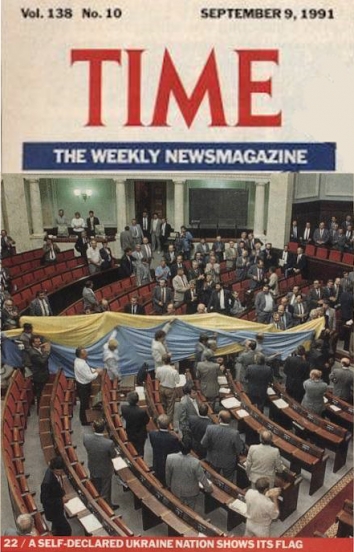

Featured Galleries USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

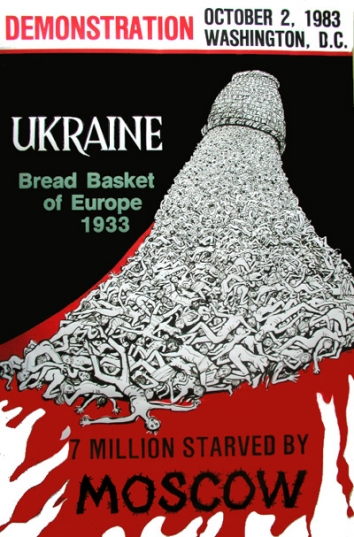

Holodomor Posters

Holodomor Posters

Vermont Yankee Announces Selection of Holtec International’s HI-STORM 100 Cask System

Holtec International, Marlton, NJ

Holtec International, Marlton, NJWed, July 29, 2015

|

|

|

|

|

| |