|

The procedures developed for DR are in full compliance with the required ASME Codes: Section III NB Class 1 components; Section V “Nondestructive Examination,” Article 2 “Radiographic Examination and Mandatory Appendix IX “Radiography using a Digital Detector System.” Holtec views DR to be particularly valuable for the nuclear industry whose historical challenges with the issues of senescence, slow deterioration and inability to rapidly retrieve archival film are now completely resolved. The instant portability and file organization of the digital images in electronic space now enables remote viewing and interpretation of the DR images by our stakeholders, anytime, anywhere. High fidelity digital images can be maintained, archived indefinitely, and rapidly retrieved from the redundant, secure Holtec hard drives when needed.

|

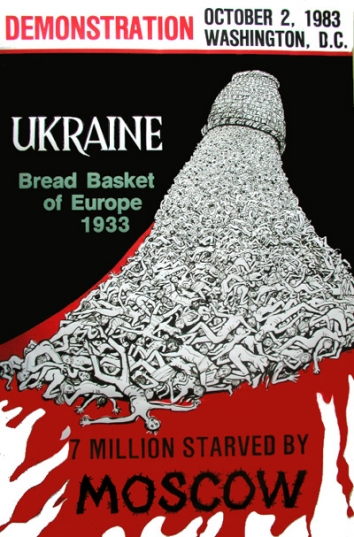

Holodomor Posters

Holodomor Posters

Holtec, Camden, USA

Holtec, Camden, USA