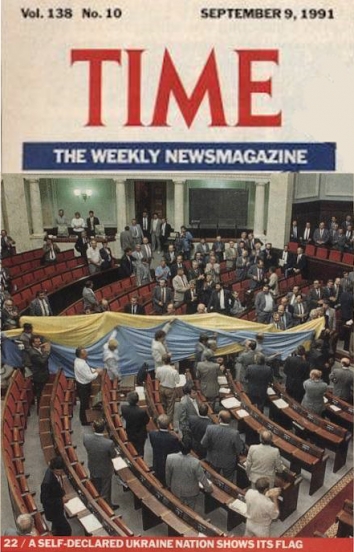

Featured Galleries USUBC COLLECTION OF OVER 160 UKRAINE HISTORIC NEWS PHOTOGRAPHS 1918-1997

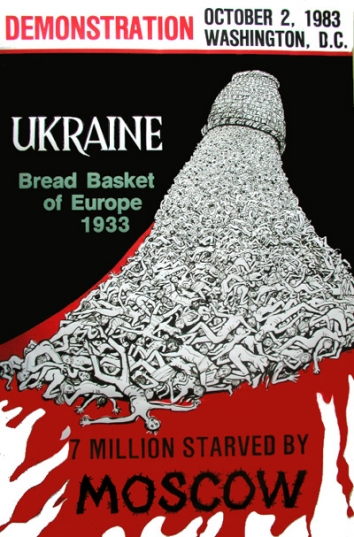

Holodomor Posters

Holodomor Posters

Innovative equipment was installed at the Central Iron Ore Enrichment Works (Central GOK) as part of the DRI-pellet project

System Capital Management,

System Capital Management,

Kyiv, Ukraine, Thu, Feb 20, 2020

Metinvest's Central GOK is the first in Ukraine to equip the beneficiation area with KDF-90 ceramic filters. Installation of new vacuum filters is part of a large-scale project of the enterprise for the production of pellets based on DRI (direct reduction of iron) technology. Investments in modernization amounted to 5 million US dollars.

The new equipment allows reducing the cost of iron ore processing. The operation of the filters is supported by a stand-alone unit with the pump, which ensures energy savings of 640 kWh vs. the dismantled DOO-100 fabric filters. KDF-90 can be supplied with a thicker mass for drying, which reduces the consumption of process water. Ceramic consumables require replacement every year and a half, while fabric replacement was required every month.

Alexander Sidletsky, Head of the Ore Beneficiation Plant at Metinvest's Central GOK:

"Following the installation of Derrick Screens at the plant, we will be producing a finer ground product. And the new vacuum filters will determine the final properties of the concentrate, its humidity, in particular. If previously it was 9.4%, it will now drop to 8.2-8.4%. Now we are performing set up operations on the new equipment, selecting the optimal mode of its operation. The ceramic filters have already demonstrated double productivity vs. their fabric equivalents."

Ceramic filter elements are designed to produce 80 to 120 tons of concentrate per hour. For comparison, the old equipment production rate was 30-40 tons per hour. The new filters will be part of the technological process set up to produce a concentrate with Fe 70.5%.

Dmitry Shevchik, General Director of PrJSC CGOK:

"Central GOK is developing the production of new class pellets, which are in demand in the international market. The overhaul of the enrichment plant sections, installation of new equipment and the earlier repair of the pelletizing plant are all part of a large-scale strategic project that opens up new opportunities for the development of Central GOK and its team."