Ukraine Conducting Dry Runs to Commission World’s First Central Storage Facility for the Country’s Used Fuel Discharged by its Russian Origin Reactors

.jpg) Holtec, One Holtec Boulevard, Camden, NJ

Holtec, One Holtec Boulevard, Camden, NJ

Nov 17, Wed, 2021

|

Ukraine National Nuclear Energy Company “Energoatom” is poised to begin moving used fuel from the nation’s operating reactors to its newly built Central Spent Fuel Storage Facility (CSFSF) (called “Consolidated Interim Storage (CIS) Facility” in the U.S.) starting in 2022.

|

|

|

|

Ukraine’s sixteen year-long quest to establish a supremely safe consolidated interim storage facility to take full control of its used nuclear fuel is inching closer to fruition as the country’s national nuclear operator, Energoatom, goes through the final pre-commissioning trials.

|

|

|

|

This CIS facility, located inside the Chernobyl Exclusion Zone in the north of the country, will vault Ukraine to the rank of elite nations in the field of long-term stewardship of used nuclear fuel which many consider to be a necessary predicate for the renaissance of nuclear energy in a country in need of retiring its aging fossil power plants.

|

|

|

|

On November 6, 2021, Energoatom Acting President Mr. Petro Kotin witnessed the successful demonstrational tests of critical heavy load handling and fuel loading evolutions at the Rivne Nuclear Power Plant. Further details may be found in Energoatom’s website linked here.

|

|

|

|

|

|

Central Storage Facility: Energoatom Acting-President Mr. Petro Kotin (Left) and Minister of Energy of Ukraine Mr. German Galushchenko (Right) in Front of Holtec-Engineered Canister Transfer Device Located in Cask Receiving Building

|

|

|

Ukraine produces more than half of the country’s electrical energy from its 15 nuclear reactors and boasts Europe’s third largest commercial nuclear program. The ability to control and safely manage its used fuel on its own territory is a strategic need as well as a matter of financial prudence for Ukraine in light of the fact that the in-country fuel storage facility is projected to accrue Energoatom some $200 million each year in today’s dollars through avoided payment to the Russian Federation. “The soon-to-be-commissioned CSFSF is a fitting symbol of Ukraine’s resolve to achieve complete operational independence in regard to management of its spent fuel discharged by the country’s fleet of reactors and provide a safe and economic solution for long-term management of used nuclear fuel at its domestic centralized storage facility. This facility will make Ukraine an international leader in consolidated storage of spent nuclear fuel,” says Holtec’s Vice President of Ukraine Operations, Mr. Riaz Awan.

|

|

|

|

We are proud to have provided Energoatom state-of-the-art storage and transport systems for its Russian-origin (VVER) nuclear fuel, an innovative canister transfer system and a host of ancillaries with proven defense-in-depth features against accidents and mishaps. Some of the major equipment types include the HI-STORM 190 vertical ventilated storage system, the HI-STAR 190 Universal Transport Cask, the HI-TRAC 190 Transfer Cask, and an array of ancillary equipment to load, dehydrate, and weld the double wall Multiple Purpose Canisters at each operating plant site. The dried and welded Double Wall Canisters shall be safely transported in the HI-STAR 190 transport cask to the Central Storage Facility and placed in the HI-STORM 190 vertical ventilated systems for environmentally safe-storage. The high-capacity Double Wall Multi-Purpose Canisters and world’s most thermally efficient transport cask HI-STAR 190 will become Ukraine’s workhorse to transport the country’s used fuel from its nine reactors to the nation’s consolidated interim storage facility. Although the Design Life of CSFSF is 100 years, we expect their Service Life to be many times longer.

|

|

|

|

|

|

Central Storage Facility: HI-STORMs (Wrapped) Arrayed in Front of the Cask Receiving Building

|

|

|

|

Central Storage Facility: Vertical Cask Transporter with Empty HI-STORM in Front of the Cask Receiving Building

|

|

|

The initial contract agreement provides for ninety storage systems, five transport casks, three transfer casks, five rail cars, and an array of ancillary equipment. All equipment needed to complete the first loading operation has now been delivered to Ukraine despite Covid-caused delays.

|

|

|

|

A gallery of captioned photos below provides a glimpse into the new CSFSF and Holtec-supplied systems, components, and structures.

|

|

|

|

Finally, we would like our readers in Ukraine to know that Holtec is recruiting engineers for our Kyiv Operations Center, as we expand and strengthen our engineering workforce in Ukraine for existing and future projects. Interested applicants may contact Vice President Mr. Riaz Awan at r.awan2@holtec.com for additional information.

|

|

|

|

|

|

Central Storage Facility: HI-STAR 190 Lifted by the Cask Receiving Building’s Main Crane Using the HI-STAR Lift Yoke

|

|

|

|

Central Storage Facility: HI-STAR and the Canister Transfer Device in the Cask Receiving Building

|

|

|

|

|

Central Storage Facility: Holtec-Supplied Vertical Cask Transporter

|

|

|

|

|

Rivne NPP: HI-TRAC 190 Transfer Cask on the Holtec-Supplied Rail Car

|

|

|

|

|

Top View of the Double Wall Multi-Purpose Canister (MPC-31) Containing Holtec-Patented METAMIC-HT Neutron Absorber for Storing and Transporting VVER Fuel

|

|

|

|

|

Holtec-Patented Forced Helium Dehydrator, Also Used in the Chernobyl Dry Storage Project; in Use at Over 30 Nuclear Units

|

|

|

|

|

Rivne NPP: HI-STAR 190 Transport Cask with Impact Limiters on the Specially-Designed Holtec-Supplied Rail Car

|

|

|

HI-STAR 190 Transport Cask on the Specially-Designed Rail Car Headed to the Central Storage Facility; the Rail Spur Built by Energoatom

|

|

|

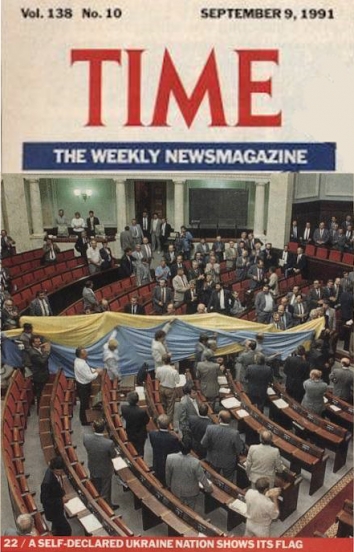

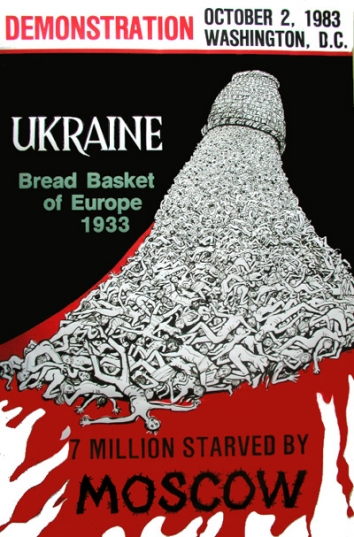

Holodomor Posters

Holodomor Posters

.jpg) Holtec, One Holtec Boulevard, Camden, NJ

Holtec, One Holtec Boulevard, Camden, NJ